Empowering Industries with Cutting-Edge PLC Automation Solutions

PLC Automation Solutions

PLC Automation refers to the use of Programmable Logic Controllers (PLCs) to control industrial machines, processes, or entire systems. It’s a key component in modern industrial automation.

PLC Automation using C# typically involves creating a PC-based application that communicates with a PLC over an industrial protocol (like Modbus, OPC UA, Ethernet/IP, or Siemens S7 Protocol). This allows you to monitor, control, or log data from a PLC using a custom-built C# application.

Our experienced team specializes in developing projects, designed to modernize remote monitoring and control systems. data analysis, machine learning, and artificial intelligence, delivering tailored solutions that align with your unique business goals. Built using C#.NET technology, our powerful solutions enables businesses to effortlessly manage sensors and hardware devices from any PC on a TCP/IP network—whether via Ethernet or Wi-Fi. It offers real-time access to essential data and control capabilities, making it ideal for large-scale environments where precision and efficiency are critical.

Transform your factory floor data into actionable intelligence with our expert PLC automation data integration for Power BI dashboards.

Our system prioritizes convenience and control, allowing authorized users to monitor and operate equipment across multiple locations with ease. This enhances operational productivity while reinforcing safety protocols.

Applications

In manufacturing, it can enhance production efficiency by enabling centralized, real-time monitoring of equipment and sensors, reducing downtime and improving workflow.

In the energy sector, it offers the ability to remotely oversee power generation and distribution systems, supporting optimal performance and proactive maintenance.

In the healthcare field, the system can be applied to monitor and control medical devices, contributing to improved patient safety and care quality.

In agriculture, it can automate irrigation and track environmental conditions, helping to maximize crop yields and resource efficiency.

Additionally, in research and development, this technology enables remote control of scientific instruments and experimental setups, enhancing data accuracy and operational flexibility.

Overall, the system’s capabilities open up wide-ranging opportunities for innovation and efficiency across industries such as manufacturing, energy, healthcare, agriculture, and scientific research.

Customization Options for Industries

The project’s distinctive features enable seamless customization and adaptation across a wide range of industrial applications, meeting the increasing demand for automation in modern businesses. Designed to operate over a TCP/IP network using Ethernet or Wi-Fi, the remote monitoring and control system can be tailored to specific industry requirements, allowing efficient management of hardware components and sensors.

This adaptability makes the solution ideal for sectors such as manufacturing, processing, and logistics, where real-time oversight and control are critical. In manufacturing environments, the system can monitor machine performance and manage production processes remotely. In logistics, it can be employed to track inventory, manage assets, or monitor environmental conditions during transport.

Our Solution Includes:

✅ Seamless data capture from all major PLC brands via OPC UA, Modbus TCP, Ethernet/IP, and custom protocols

✅ Robust data logging into SQL Server Database.

✅ Custom Power BI dashboards tailored to YOUR factory’s KPIs

✅ Scheduled refresh & real-time alerts for instant action

✅ Scalable architecture designed to grow with your operation

Tag Tracker Service

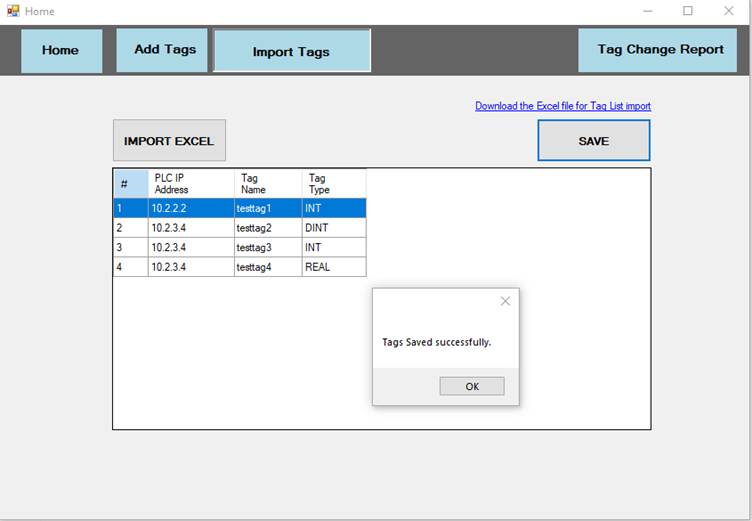

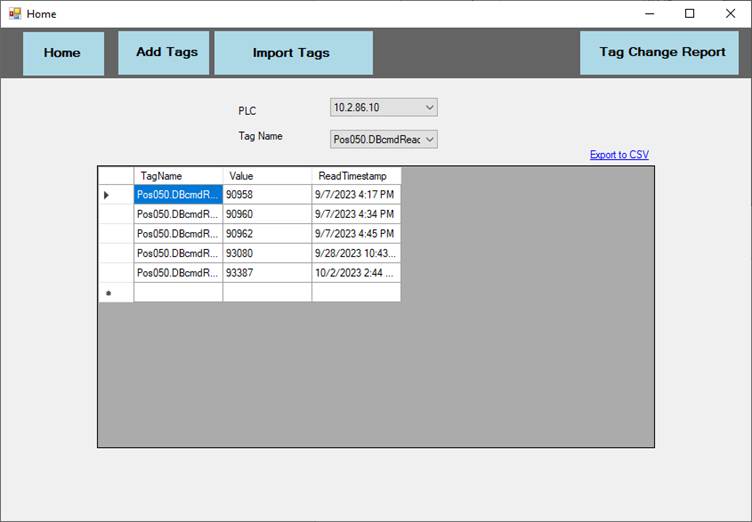

We have developed a Tag Tracker system which can be configured on a machine to configure all the tags to be monitored and to capture Tag Data for reporting purpose. “Tag Tracker” can ensure that all machine or process data is logged in a secure database that cannot be edited or deleted.

Tag Tracker historical data can be used to provide automatic hourly, shift, daily, weekly, monthly, quarterly reports. Tag Tracker historical data can ne used to build a dataset for ML and AI agents.

Here are some screenshots of Tag Tracker

Partner with Digiketing for PLC Automation Services

Join the growing list of businesses who trust Digiketing Software Consulting Pvt Ltd as their partner for PLC Automation services. Contact us today at [email protected] to learn more about how we can help you incorporate PLC Automaiton into your operations and reap the benefits of this innovative technology.